Hydnum Steel presents its green steel project in the Congress of Deputies: zero emissions, zero discharges and renewable energy to decarbonise the steel industry

- The company’s CEO, Eva Maneiro, has asked the Industry Committee for institutional support for this key initiative for the transition to a zero carbon footprint economy

- The future plant will avoid almost five million tonnes of CO2, a figure equivalent to the annual emissions of all the vehicles in a large city such as Madrid

Hydnum Steel has presented to the Industry Committee of the Congress of Deputies its ambitious project to transform the steel industry in Spain and Europe, building the first plant on the Iberian Peninsula that will operate without fossil fuels, using renewable energy and green hydrogen. A vital pioneering step towards the total decarbonisation of steel, an industry that accounts for 9% of global CO2 emissions.

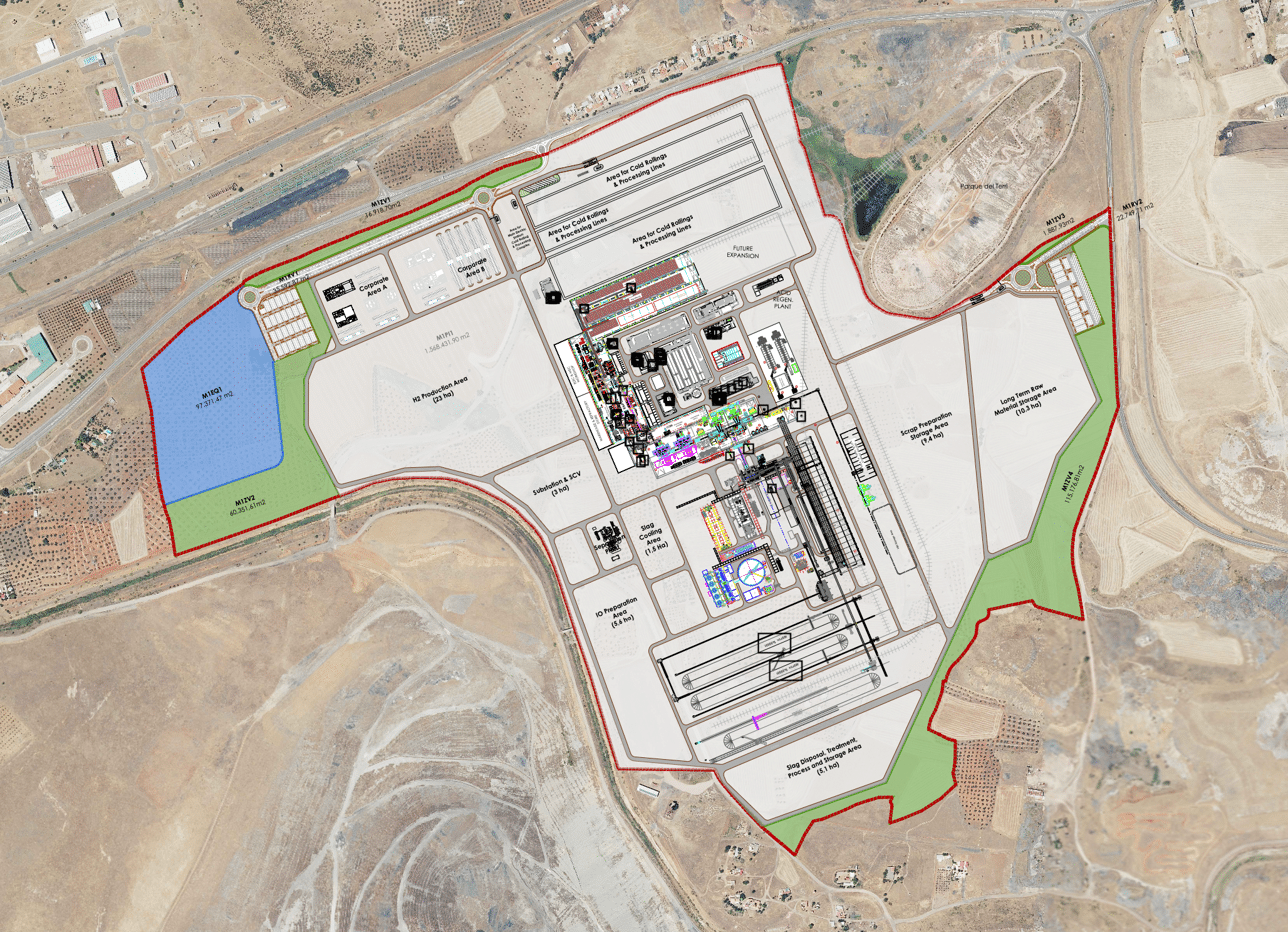

“Another way of producing steel is possible”, said Eva Maneiro, Hydnum CEO. “Our target is clear: to manufacture green steel, completely emission-free, with no discharges into the environment”. Located in Puertollano, the new plant will be a model of water sustainability thanks to its pioneering waste water reuse system. “We are going to show that it is possible to produce steel without compromising the planet’s future, taking care of every single drop of water”, she added.

This extraordinary session was attended by Inés Granollers, Chairperson of the Industry and Tourism Committee of the Congress of Deputies, as well as members of the Bureau, representatives and members of the Committee, who requested that Hydnum Steel attend to report on all the details of this project.

Technological innovation and water sustainability

One of Hydnum Steel’s most innovative features will be the use of the Gemelo Digital (Digital Twin) developed together with Siemens, the project’s strategic partner, which will optimise all aspects of the production process in real time, thus improving energy efficiency and reducing the consumption of resources. This makes the plant not only a benchmark for sustainability, but also a model of production efficiency.

However, Hydnum’s commitment is not limited to the elimination of emissions. The plant will be a pioneer in water management, using cutting-edge technology to treat and reuse grey water and waste water, and completely eliminating discharges into the environment. “The steel industry has traditionally been a big consumer of water, but at Hydnum Steel we are going to change that”, explained Maneiro. “We want our plant to be a benchmark in water sustainability, which means not only producing steel in a clean way, but also doing so without compromising water resources”.

An economic and social impact in the heart of Spain

The plant’s location in Puertollano is no accident. With solid industrial infrastructure, the region is already a strategic hub for the production of green hydrogen and renewable energy, key elements for the project’s success. In addition, the plant will create more than 1,000 direct jobs and around 5,000 indirect jobs, revitalising an area with high unemployment rates, especially among young people.

“The economic impact will be significant”, said Maneiro. “This project will not only transform the steel industry, but will also boost the reindustrialisation of a key region, attracting foreign investment and promoting the development of new clean technologies”. The plant also has the support of the Government of Castilla-La Mancha, which has declared it a Priority Project, recognising its strategic importance both locally and nationally.

Spain, leader in green hydrogen and renewable energy

Maneiro also highlighted Spain’s role as an international leader in green hydrogen and renewable energy. “A few weeks ago, we participated in a green steel summit in Dubai and the perception about Spain was clear: we are leading the way in the adoption of green hydrogen as a clean energy source”, she said. This leadership, she stressed, is a competitive advantage that positions Spain on the global energy transition map.

Hydnum Steel will not only contribute to reducing the steel deficit in Europe, but will also position Spain as a benchmark in sustainable steel production in a market in which demand continues to grow. This international recognition reinforces the importance of continuing to

invest in projects like Hydnum, which not only have a positive impact on the environment, but also on Europe’s energy and industrial autonomy.

Institutional support and the need to act now

Maneiro concluded with a clear appeal: “The time to act is now”. She underlined the importance of institutional and financial support for the project to get off the ground in 2025, and stressed the need to join forces with other strategic actors to secure the necessary financing. Hydnum Steel, she said, is more than a steel plant: “It is a key project for Europe’s industrial and energy independence, and for the decarbonisation of one of the most polluting industries on the planet”.

“We are convinced that this project will not only transform the steel industry, but will also help protect our planet for future generations”, Maneiro concluded, making it clear that the company is ready to lead the change towards a cleaner, more sustainable future.