Hydnum Steel chooses Puertollano to build one of Europe’s first green steel production plants

- Hydnum Steel is a new-generation steel plant technologically prepared to use non-fossil energy in the production process.

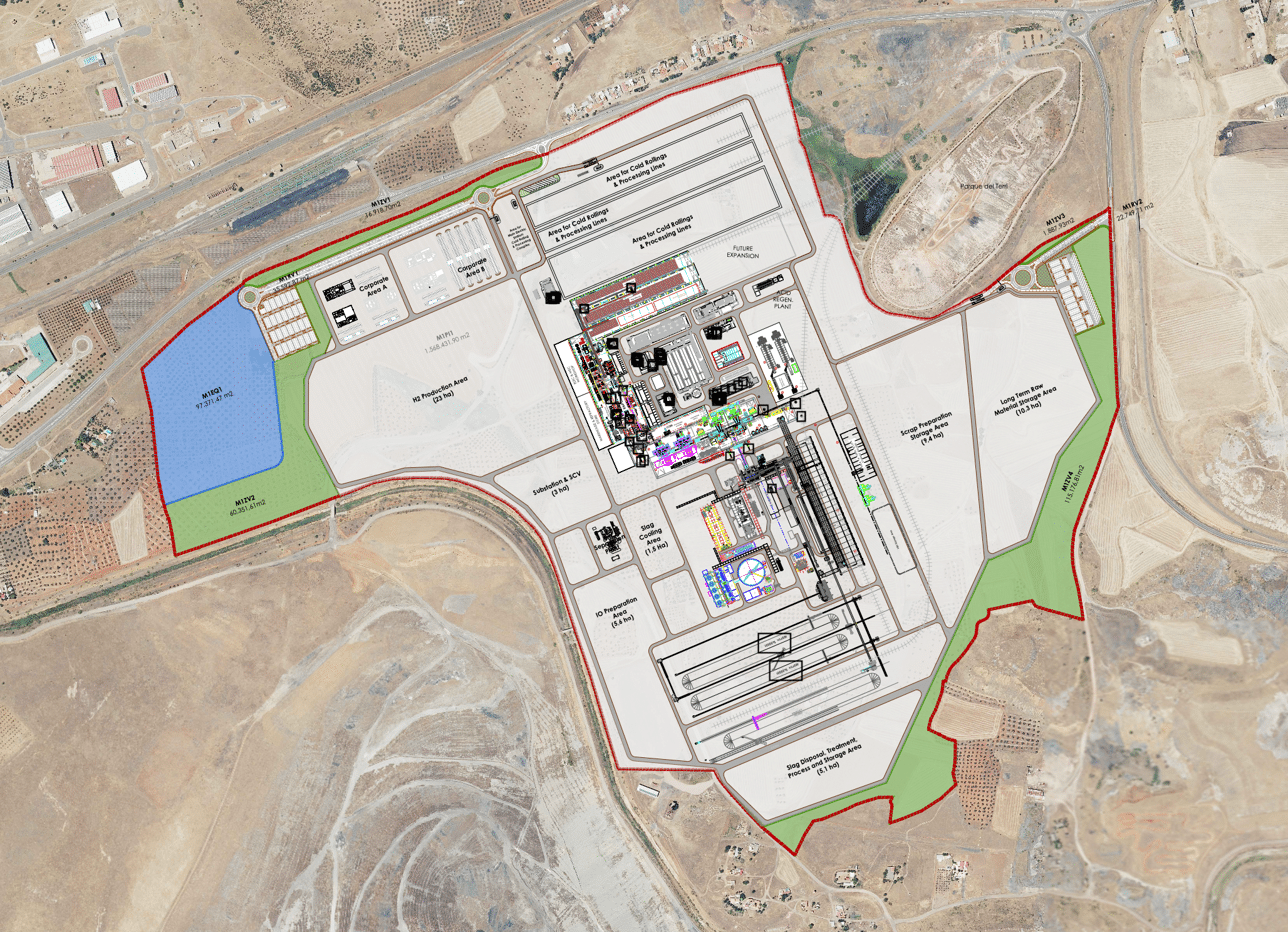

- The plant has a footprint of 1.3 million m2.

- The first project phase requires an initial investment of € 600 M and will create 400 direct jobs.

- The project counts on Siemens as a technological partner to guarantee its sustainability with solutions under the concept of digital factory and decentralized energy system.

- Also participating are ABEI Energy, which brings its long international experience in renewable energy production, and Russula Corporation, which has been providing advanced engineering solutions to the world’s leading steel producers for decades.

February 21, 2024. Hydnum Steel has informed the Castilla-La Mancha regional government of its intention to build a green steel production plant. It will be the first greenfield steel plant in the Iberian Peninsula designed from the ground up that uses non-fossil energy throughout the manufacturing process. And one of the first in Europe. Renewable hydrogen will progressively be incorporated in the production process with the aim of substantially reducing CO2 emissions.

The plant has a footprint of 1.3 million m2. The first project phase requires an initial investment of € 600 M and will create 400 direct jobs. The total planned investment exceeds €1 billion euro.

Puertollano was chosen because of its strategic location, close to the logistic nodes of central, southern, and eastern Spain, as well as Portugal; many hydrogen production projects are already in operation; the suitability and availability of land for the generation of renewable energies such as solar and wind. In addition, the presence of the National Hydrogen Center, headquartered in Ciudad Real, opens the possibility of establishing alliances.

Hydnum Steel believes Puertollano has an ideal ecosystem for the implementation of a green steel production plant, taking advantage of the synergies of the environment and, at the same time, becoming an important flagship project at both the local and regional level.

Eva Maneiro, CEO of Hydnum Steel, thanked the institutional support for the project. “Puertollano has a great mining and industrial past and from now on we want it to be a reference for the industry of the future, designed with environmental awareness and responsibility. It will be an honor for all the companies involved to develop this exciting project,” she said.

The steel industry of the future: Emission-free, Digital, and Sustainable

The steel industry is responsible for approximately 9% of carbon dioxide emissions worldwide and 7% in the European Union. Hydnum Steel will be built with new-generation technology designed to replace the use of fossil fuels with renewable hydrogen, thus contributing to the decarbonization of the sector.

The green plant’s production will be highly efficient, automated, and safe through the application of new technological developments in digitization, vision, and artificial intelligence. It will also be in tune with the Sustainable Development Goals (SDGs) focused on the steel sector by orienting measures framed within the circular economy; recycling scrap as raw material, minimizing water usage, and assessing waste and by-products generated during manufacturing.

Hydnum Steel upholds a commitment to reindustrialization, wealth generation and job creation. In addition to its local impact, its goal right from the outset was to strengthen the autonomy of the domestic market, both national and European, mitigating the trade deficit of a strategic product such as steel. The plant aims to become a model of decarbonization for the industry and a benchmark in the roadmap towards energy autonomy in Europe.

Collaboration

The Hydnum Steel project is being implemented through a close collaboration between Siemens, ABEI Energy and Russula Corporation.

As a technological partner, Siemens will provide solutions related to the digital factory in the design, manufacturing, and maintenance phases of the plant. These solutions, based on the Digital Twin concept, include design and simulation software, industrial automation systems, control and monitoring systems, cybersecurity, sustainability, artificial intelligence, and predictive maintenance.

Agustín Escobar, president, and CEO of Siemens Spain, believes that this project “will not only have a positive effect on its own facilities in the area of carbon footprint reduction. It will also impact industries such as the automotive and marine sectors, where the use of greener steel will help them meet their decarbonization goals. Siemens is proud of this new plant, which will be a benchmark in the digital and sustainable transformation of the steel sector”.

ABEI Energy will bring its long-standing international experience in renewable energy and hydrogen production, and Russula will provide technical management and engineering development.

The scale and nascent innovation aspects of this project provide a unique opportunity for more investors and technology stakeholders to join the strategic alliance. Hydnum Steel has sought public-private collaboration with the Spanish Government, through the Regional Government of Castilla-La Mancha, to access funding from the Decarbonization PERTE, strategic projects with a great capacity to drive economic growth.

To ensure the sustainability of the project, Siemens will help reduce its carbon footprint with technology based on a decentralized energy system that facilitates the integration of renewable technologies and the decarbonization of the industrial process. The company will supply digital applications that manage emissions in a quick and flexible manner thereby generating energy costs savings for the green project.

ABEI Energy is an independent producer that fully manages electricity generation projects from renewable sources in countries such as Spain, the United States, the United Kingdom, France, Italy, and Poland, and provides expertise in the production of green hydrogen.

Russula Corporation has been supplying innovative technological solutions to major steel producers around the world for decades.

The scale and nascent innovation aspects of this project provide a unique opportunity for more investors and technology stakeholders to join the strategic alliance.

More information

Press Department. 663 932 337